Battery Breakthroughs at Sea: The Next Wave of Maritime Electrification

Key Highlights

- Marine batteries are increasingly vital for decarbonizing shipping, offering immediate environmental and operational benefits, especially in short-sea and hybrid configurations.

- Current energy density limitations and infrastructure gaps pose challenges for deep-sea electrification, but technological advances and port investments are driving progress.

- Successful deployment relies on modular battery architectures, load-following strategies, and strong regulatory support, with lessons learned from global case studies like Norway and Canada.

- Emerging innovations such as solid-state batteries and hybrid architectures with alternative fuels promise to enhance energy density, safety, and economic viability in the future.

- Harmonized international standards and coordinated infrastructure development are essential to accelerate the global adoption of marine electrification and realize its full environmental and operational potential.

The momentum behind maritime electrification is accelerating, as shipowners weigh propulsion strategies that can satisfy tightening emissions rules while preserving operational efficiency and long-term commercial performance. A growing body of analysis now points to battery systems as a practical pathway for shipping’s near-term decarbonization, particularly as hybrid powertrains gain traction across both coastal and deep-sea fleets.

According to the latest ABS Sustainability Outlook 2025, batteries are no longer confined to niche ferry operations or harbor craft. Instead, hybrid marine battery architectures are emerging as a critical bridge technology, capable of reducing fuel burn, supporting redundancy, and enabling lower-carbon voyages ahead of the large-scale availability of alternative fuels.

While current installations are predominantly hybrid, reflecting constraints around energy density and global charging infrastructure, the report argues that full battery-electric operation could become viable over longer distances as technology matures. Future enablers include modular battery-swapping, expanded shoreside charging capacity and standardized electrification corridors across major trade routes, developments that could allow batteries to serve as the backbone of next-generation propulsion ecosystems.

Beyond the short-sea segment, battery-electric propulsion is beginning to influence vessel design in more complex operational theaters. What was once regarded as an auxiliary power enhancement is now being integrated into the propulsion mix for offshore support vessels, cargo ships, and other deep-sea tonnage, signaling a step change in how the sector views energy storage at sea.

ABS positions electrification as one of the fastest-deployable decarbonization levers currently available to shipowners. Even as questions persist around chemistry selection, lifecycle economics and thermal management, hybrid and fully electric configurations are already demonstrating tangible emissions reductions.

In hybrid mode, battery packs can buffer load swings, smooth transients, and support load-following strategies that cut fuel consumption and optimize engine performance over varying duty cycles.

These operational efficiencies extend into maintenance and noise profiles. Battery-assisted vessels typically run engines at more stable loads, reducing wear and extending service intervals. At the same time, lower radiated noise and reduced particulate output offer environmental co-benefits, attributes that are increasingly relevant for operations near ports, environmentally sensitive waters and urban coastal zones.

The report suggests that the acceleration in adoption is as much about operational pragmatism as it is about environmental compliance. Installed battery capacity across maritime applications has grown steadily for more than a decade, with deployments maturing from early demonstrators to commercially integrated systems. The direction of travel is clear: batteries are evolving from experimental add-ons into key system components that enable broader hybridization and future fuel strategies.

Underpinning this shift are improvements in battery energy management, safety engineering, integration methods and Class rule development. ABS points to advances in redundancy design, fire suppression, and thermal propagation prevention as critical enablers for wider uptake across vessel classes with demanding safety envelopes, such as cruise, offshore, and passenger segments.

Electrification increasing the decarbonization agenda

According to ABS, vessel electrification is one of the most viable and rapidly deployable decarbonization pathways available to shipowners today. Despite questions over chemistry, energy density, and lifecycle economics, battery systems deliver immediate environmental and operational advantages.

Hybrid and fully electric systems are already proving their worth in the short-sea segment, delivering up to 30% reductions in greenhouse gas emissions in hybrid configurations and complete elimination of emissions for short-range all-electric operations. In hybrid setups, battery systems provide power redundancy, stabilize load fluctuations, and support load-following strategies, collectively cutting operational fuel costs.

The environmental dividends extend beyond carbon. Electrified vessels operate with lower radiated noise, reduced particulate emissions, and fewer moving components, which translates into lower maintenance and longer equipment life. For port cities dealing with air quality concerns and noise constraints, these co-benefits make batteries an attractive proposition for both shipowners and local governments.

From niche to necessity

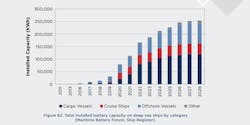

ABS’ 2025 Outlook presents compelling data showing that maritime battery adoption is no longer a niche activity. Installations on deep-sea vessels from cargo ships to offshore support vessels, are rising steadily, with installed capacity growing year-on-year since 2011. The numbers point to a structural shift: batteries are evolving from experimental add-ons to essential components in vessel design.

ABS highlights several drivers behind this growth:

- Safety and redundancy: Batteries provide critical backup power and enhanced system reliability.

- Operational efficiency: Batteries enable load balancing and peak shaving, improving energy use and reducing engine wear.

- Environmental performance: They deliver measurable cuts in greenhouse gas and pollutant emissions.

These advantages explain why, despite the limitations of current lithium-ion technology, batteries are increasingly viewed as a necessity to maritime decarbonization; not just as an endpoint, but as an enabler of fully electric and hybrid systems and emerging fuels such as hydrogen, methanol, and ammonia.

Engineering realities: Energy density meets economics

The leap from coastal to deep-sea electrification, however, remains a formidable challenge.

Today’s marine-grade lithium-ion batteries offer energy densities in the range of 0.25 to 0.3 MWh per cubic meter. For a large container vessel undertaking a long-distance voyage, the total energy demand typically reaches several thousand megawatt-hours, far exceeding the few hundred megawatt-hours required for short-range operations. At present energy density levels, meeting this requirement would necessitate thousands of cubic meters of battery volume and several thousand metric tons of mass, introducing substantial design and operational constraints.

It is important to recognize that a vessel’s total energy requirement is influenced by multiple factors, including ship size and type, cruising speed, operational profile, depth of discharge, and redundancy provisions for safety. These variables can significantly alter the overall energy demand.

Although battery-electric propulsion for long-range shipping is technically feasible, the associated weight, space, and cost implications render it impractical under current technological and infrastructure conditions.

The deep-sea sector’s diversity, spanning containerships, bulkers, cruise ships, and offshore units, means that the business case varies across vessel classes. “Developing compelling business cases for each sector remains a formidable task,” but not an insurmountable one, the report concludes.

Designing for diversity: Matching batteries to missions

A central theme in ABS’s analysis is the importance of operational profiles in determining the right battery technology. The choice between high-energy and high-power batteries depends not only on the voyage duration but also on how and where the vessel operates, and the safety systems that are integrated with the battery technology.

Short-sea ships benefit from high C-rate batteries capable of rapid charge and discharge cycles, ideal for peak load conditions such as manoeuvring or docking. Long-haul vessels, by contrast, require low C-rate batteries optimized for slow, steady discharge over extended durations. However, these require longer charging times, prompting ABS to recommend redundant cascading systems that can maintain power reliability during prolonged operations.

About the Author

Michael Kei

Michael Kei is ABS Vice President, Technology.