Coolbrook Partners with JSW Group to Decarbonize Steel and Cement Industry with RotoDynamic Heater

Coolbrook has signed a strategic cooperation agreement with JSW Group, India’s $23 billion diversified business conglomerate, to implement its RotoDynamic Heater (RDH) technology at JSW’s steel and cement manufacturing sites at Vijayanagar Works in Karnataka, India, to achieve low CO2 emissions.

As part of the agreement, both companies will collaboratively devise a roadmap aimed at achieving low-carbon production and facilitating the phased rollout of RDH technology for the JSW steel and cement manufacturing processes starting this year.

The companies’ partnership follows the successful completion of Coolbrook’s first phase of its large-scale pilot test for RDH technology at the Brightlands Chemelot Campus in the Netherlands in 2023.

The tests demonstrated the technology’s heat-generating capabilities, which surpassed 1,000°C – significantly above the range of conventional resistive heaters – and proved the technology’s capability to reach temperatures up to 1,700°C – essential temperatures required for steel production.

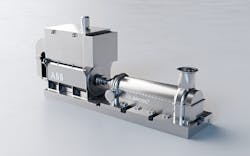

The RDH technology utilizes renewable electricity to power high-temperature industrial processes in steel and cement production and significantly reduce the need to burn fossil fuels. In steel manufacturing specifically, the technology targets the decarbonization of manufacturing processes in traditional blast furnaces and the direct reduction of iron-based (DRI-based) production of iron and steel.

According to Coolbrook, the company’s RDH technology has the potential to reduce global CO2 emissions in heavy industries by 30% - the equivalent of more than 2.4 billion tons annually – by replacing the burning of fossil fuels with electrification from renewable energy sources.

About the Author

Breanna Sandridge, Senior Editor

Breanna Sandridge is senior editor for EnergyTech and Microgrid Knowledge, both part of the energy group at Endeavor Business Media.

Prior to that, Breanna was managing editor for Machinery Lubrication and Reliable Plant magazines, both part of Noria Corp. She has two years experience covering the industrial sector.

She also is a 2021 graduate of Northeastern State University (Oklahoma) with a Bachelor's in English.