Illuminating Impact of Aluminum Oxide in Industrial HVAC: Energy Efficiency Shines at Malaysian Pharmaceutical Cold Storage

Suspending sub-micron particles of aluminum oxide in liquid and utilizing it as a heat-transfer fluid apparently has achieved a 13% reduction in heating, ventilation and air conditioning (HVAC) energy consumption at a large pharmaceutical cold-storage warehouse in Malaysia.

HT Materials Science (HTMS) and its warehouse client touted the success of its Maxwell sub-micron heat-transfer additive in operation at the DKSH warehouse at ShanAlam in Selangor. DKSH is a market expansion, delivery, storage and logistics firm serving global manufacturers.

The case study on the use of HTMS’ Maxwell fluid in the pharmaceutical cold-storage facility touted a comparative first-month energy reduction of 53,379 kWh earlier this year. DKSH and HTMS project that overall, first-year energy savings could top 600,000 kWh, more than 10% over previous consumption.

The project’s payback period could be realized in barely over two years, the companies say. Tri Quantity Sdn Bhd served as energy consultant to DKSH on the project and reported on the early results.

“This initiative not only strengthens our operational efficiency but also reaffirms DKSH’s commitment to sustainable, future-focused business practices,” Joel Solomon, head of supply chain management, DKSH Malaysia & Brunei, said.

The DKSH warehouse covers about 56,100 square meters with an air-conditioning range of more than 41,000 square meters, according to the case study on the project by Tri Quanity Sdn Bhd. The typical annual electricity consumption of the entire warehouse averaged about 5.65 million kWh per year.

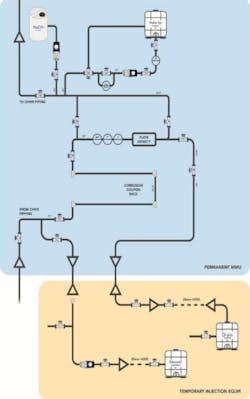

HTMS altered the chilling water loop system by fitting all the pumps with new silicon carbide seals while deploying the Maxwell Sub-Micron coolant. The Maxwell fluid was then injected into the pump discharge side of the HVAC system.

The targeted concentration of Maxwell fluid was achieved at 2% of liquid volume in the system. The injection also increased the system fluid density by 6%.

“This installation demonstrates that smart, science-driven HVAC technologies can deliver immediate cost savings and long-term sustainability benefits,” Thomas Grizzetti, CEO of HTMS, said. “We’re proud to partner with forward-thinking companies like Tri Quantity and DKSH who are helping to set the standards for energy efficiency in large-scale commercial facilities.”

HTMS says the Maxwell fluid is non-toxic and recyclable.

Energy efficiency is often termed as the “first fuel” in reduction of both consumption, costs and greenhouse gas emissions. The U.S. Energy Information Administration has estimated that HVAC systems account for approximately 40% of total energy consumption in commercial buildings and perhaps a third of usage in industrial facilities.

The DKSH warehouse covers about 56,100 square meters with an air-conditioning range of more than 41,000 square meters, according to a report on the project by Tri Quantity Sdn Bhd. The typical annual electricity consumption of the entire warehouse averaged about 5.65 million kWh per year.

HTMS altered the chilling water loop system by fitting all of the pumps with new silicon carbide seals while deploying the Maxwell Sub-Micron coolant. Once piping and electrical connections were updated, the Maxwell fluid was injected into the pump discharge side of the HVAC system.

The targeted concentration of Maxwell fluid was achieved at 2% of liquid volume in the system. The injection also increased the system fluid density by 6%.

“This installation demonstrates that smart, science-driven HVAC technologies can deliver immediate cost savings and long-term sustainability benefits,” Thomas Grizzetti, CEO of HTMS, said. “We’re proud to partner with forward-thinking companies like Tri Quantity and DKSH who are helping to set the standards for energy efficiency in large-scale commercial facilities.”

HTMS says the Maxwell fluid is non-toxic and recyclable.

Energy efficiency is often termed as the “first fuel” in reduction of both consumption, costs and greenhouse gas emissions. The U.S. Energy Information Administration has estimated that HVAC systems account for approximately 40% of total energy consumption in commercial buildings and perhaps a third of usage in industrial facilities.

About the Author

Rod Walton, EnergyTech Managing Editor

Managing Editor

For EnergyTech editorial inquiries, please contact Managing Editor Rod Walton at [email protected].

Rod Walton has spent 17 years covering the energy industry as a newspaper and trade journalist. He formerly was energy writer and business editor at the Tulsa World. Later, he spent six years covering the electricity power sector for Pennwell and Clarion Events. He joined Endeavor and EnergyTech in November 2021.

Walton earned his Bachelors degree in journalism from the University of Oklahoma. His career stops include the Moore American, Bartlesville Examiner-Enterprise, Wagoner Tribune and Tulsa World.

EnergyTech is focused on the mission critical and large-scale energy users and their sustainability and resiliency goals. These include the commercial and industrial sectors, as well as the military, universities, data centers and microgrids. The C&I sectors together account for close to 30 percent of greenhouse gas emissions in the U.S.

He was named Managing Editor for Microgrid Knowledge and EnergyTech starting July 1, 2023

Many large-scale energy users such as Fortune 500 companies, and mission-critical users such as military bases, universities, healthcare facilities, public safety and data centers, shifting their energy priorities to reach net-zero carbon goals within the coming decades. These include plans for renewable energy power purchase agreements, but also on-site resiliency projects such as microgrids, combined heat and power, rooftop solar, energy storage, digitalization and building efficiency upgrades.